Rock wool has become one of the most important insulation materials in modern construction due to its excellent fire resistance, thermal insulation, and sound absorption properties. As global building standards continue to emphasize energy efficiency and fire safety, the demand for high-quality rock wool products is steadily increasing.

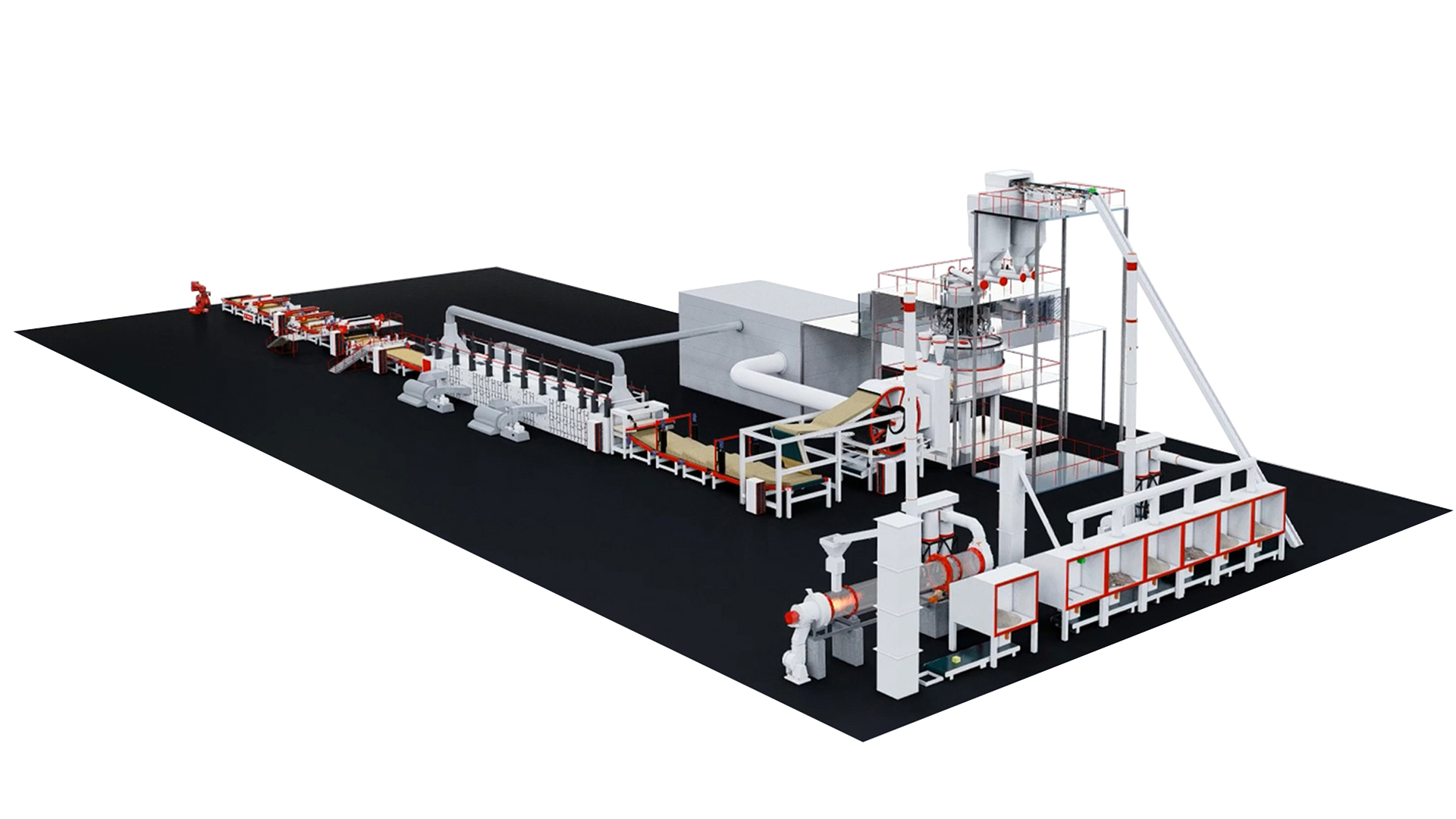

Behind stable and consistent rock wool products lies a well-designed and highly automated rock wool production line. Modern production lines are no longer focused only on output capacity, but also on fiber quality, density control, energy efficiency, and production stability. This article introduces the key technologies that define modern rock wool production lines and explains how they contribute to reliable manufacturing results.

The melting system is the core of any rock wool production line. Basalt, dolomite, and other mineral raw materials must be melted at high temperatures to form molten lava suitable for fiberizing.

Modern melting systems focus on:

Stable temperature control

Uniform chemical composition

Continuous molten flow

Advanced furnace designs help reduce temperature fluctuations and ensure consistent melt quality. Proper raw material proportioning and automated feeding systems play a crucial role in maintaining stable fiber properties and minimizing defects in the final product.

Fiberizing is one of the most critical processes in rock wool production. The molten material is transformed into fine fibers using high-speed spinning wheels or advanced fiberizing units.

Key technical factors include:

Wheel speed and alignment

Molten flow consistency

Fiber diameter control

Modern fiberizing systems are designed to produce uniform fiber distribution, which directly affects insulation performance, mechanical strength, and surface appearance. Improved fiberizing technology also reduces shot content and enhances product consistency.

After fiber formation, binders are applied to bond fibers together and provide structural stability. Accurate binder spraying and distribution are essential to avoid weak spots or excessive binder consumption.

Modern rock wool production lines utilize:

Automated binder spraying systems

Precise dosage control

Optimized curing ovens

Curing temperature and residence time must be carefully controlled to ensure proper bonding without compromising fiber integrity. Automated curing systems improve product quality while reducing energy consumption.

Automation is a defining feature of modern rock wool production lines. From raw material feeding to final cutting and stacking, automated systems ensure stable operation and consistent output.

Integrated control systems synchronize different production stages, ensuring smooth material flow and minimizing downtime. Many industrial manufacturers now emphasize turnkey solutions that combine automation, process integration, and long-term operational stability.

This approach helps manufacturers shorten commissioning time and reduce operational risks.

Accurate cutting systems ensure that finished rock wool boards meet strict dimensional tolerances. Modern cutting units operate at high speed while maintaining clean edges and minimal material waste.

Automated stacking and packaging systems further enhance production efficiency by:

Reducing manual handling

Protecting product surfaces

Improving logistics efficiency

These systems contribute to lower labor costs and safer working conditions.

Energy efficiency is an increasingly important factor in rock wool manufacturing. Modern production lines incorporate energy-saving technologies such as heat recovery systems and optimized furnace insulation.

Environmental control systems help reduce emissions and comply with local regulations. These improvements not only reduce operating costs but also support sustainable manufacturing practices.

Modern rock wool production lines integrate advanced melting, fiberizing, automation, and quality control technologies to meet the growing demand for high-performance insulation materials. Stable production, precise control, and energy efficiency are now essential requirements rather than optional features.

For manufacturers planning new facilities or upgrading existing lines, understanding these key technologies is critical to achieving long-term production reliability and product quality in an increasingly competitive market.

Hebei Guangxing Machinery Technology Co., Ltd (Guangxing), established in 1987, is one of the leading Rock Wool Production Line Supplier China and manufacturers of EPS, PU/Phenolic/Rock/Glass wool insulation panel production equipment. Guangxing enjoys a strong reputation both domestically and internationally and holds CE and ISO 9001:2008 certifications, with over 20 patents.

Copyright © 2025 Hebei Guangxing Machinery Co., Ltd. All Rights Reserved.